How Castem's "Digital Cast" service reduced lead times, allowed for process validation, turned two pieces into a single part and ultimately cut costs.

Background:

Component: Manifold Flange for an Exhaust Assembly

Material: Originally 303 Stainless Steel for ease of machining. Changed to 304 Stainless Steel for “Digital Cast” prototype and production parts.

What is “Digital Cast”?

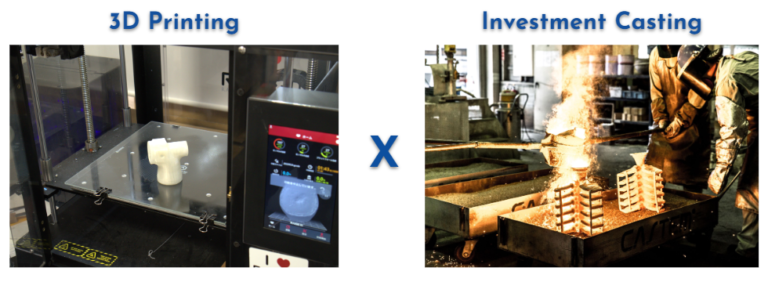

Digital Casting is a combination of the new and the old.

We are taking modern Additive manufacturing / 3D Printing Technology and applying it to traditional manufacturing processes. In our case this is Investment Casting.

The Problem

The customer, a performance motorcycle exhaust system manufacturer, faced an all too familiar problem.

- Problem 1 – They have a component / assembly product that was bottlenecking their production floor.

- Problem 2 – Their OEM customer was scheduled to put a new product that featured the component / assembly.

- Problem 3 – The component / assembly is an existing product, and if the manufacturing process on a component changes, it requires the OEM to validate the new component.

The Solution – Digital Casting

Optimal Design Proposal:

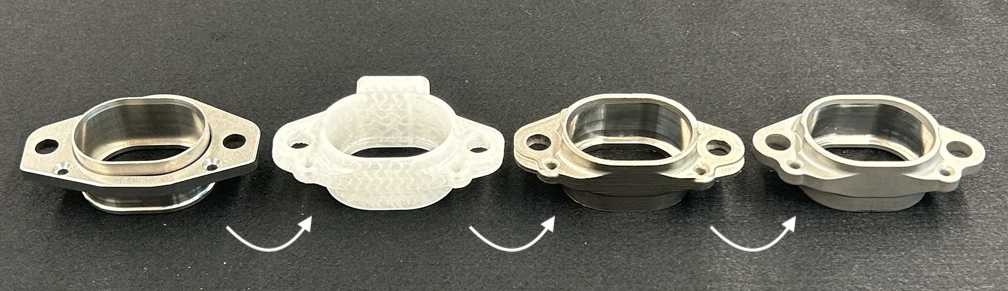

Take the original component and turn it into a single cast component.

Digital Cast Prototype:

The customer had a two week deadline in order to receive these prototype components, secondary machine the mating feature, and assemble the components. They would then send the assemblies to their customer for endurance testing and final validation of the new component.

The “Digital Cast” prototypes were delivered in time.

From Prototype to Production

Digital Casting helped streamline the prototyping process all the way to production.

Since the Digital Cast prototype was designed with Investment Casting in mind, the design information is easily reflected in the final production product, which lessen the time to production.

Cost Reduction

Let’s talk money.

As mentioned above, the customer shared that the original component was causing a bottleneck on their production floor.

The flange part of the component was laser-cut then machined. The inner component was machined.

For this inner oval shaped component alone, the average machining cycle time was over 30 minutes.

The final single cast component only required machining on the inner mating feature and reduced the machining cycle time to mere minutes. Ultimately saving the customer time and money.

Let’s not forget that the new design was 10 times more durable than the original component and performed perfectly on the endurance test.

Please reach out at info@castem.com or call us at 949-543-0274 to inquire about more information regarding Castem’s Digital Cast service.

↓Share on a social media

Explore more case study articles

“Digital Cast” – The Gift That Keeps on Giving

How Castem’s “Digital Cast” service reduced lead times, allowed for process validation, turned two pieces into a single part and ultimately cut costs. Background: Component:

Top CT Scan of Halloween’s Most Popular Candy – Reese’s Peanut Butter Cup

It is nearly that time of year again, when the little ghouls and goblins in their wonderful costumes come knocking at your door with a

The CT Scan Gets Spooky

Have you ever seen the inside of a pumpkin? Of course, you have! Every Halloween people slice open pumpkins and remove the innards which